New product launch

Full link integration design Highly integrated

Signalfire fusion splicer AI-10A is a full-link integrated design of the fourth generation of optical fiber fusion splicer,it combines high-precision electric cleaver,

optical fiber splicing into one, while integrating the OPM and VFL function, with the 8-in-1 signal fire stripper,

can be combined with the work bench and work stool, making it a new generation of optical fiber fusion splicer in the real

sense of the world, small size, light weight, easy to operate.

So small and yet so extraordinary

With innovative and friendly design

Signal Fire optical fiber fusion splicer AI-10A optical fiber fusion splicer uses a number of patents,

the full weight of the main machine,

the toolbox and a complete set of accessories is only 4.5KG,

and the toolbox size is 25.5cmx16.5cm x23cm.

Metal body with beautiful details

Used in telecom, mobile, Unicom, radio and television operators,

posts and telecommunications, railway engineering companies

and institutions of optical cable line construction, line maintenance,

emergency repair, security monitoring and research institutes research, teaching.

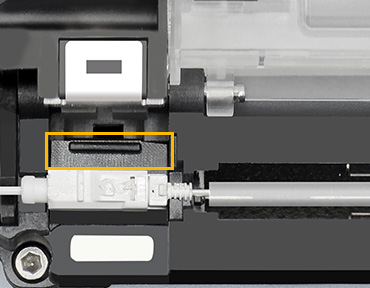

Quipped with electric

High-precision cleaver

After optical fiber is placed, the cover closed and automatically cut

The blade cuts at a random point

No blade resurfacing

maintenance free

Patented technology

for precise cutting

The key to the quality of splicing fiber is not only the quality of

the fusion splicer, but also the cleaver and various auxiliary

tools are very important, especially the trouble-free time

of the fiber cleaver and the average cutting quality,

to a large extent, determine the real splicing quality

and splicing efficiency.

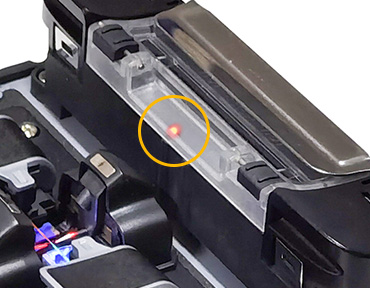

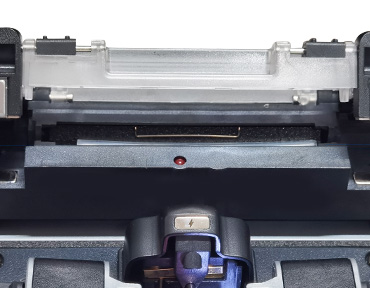

Built-in VFL and OPM function

Effectively measure connection losses, verify continuity, and help evaluate

fiber link transmission quality

OPM:Switch between six states

Wavelength: 850nm; 1300nm, 1310nm,1490nm, 1550nm, 1625nm

VFL:Switch between three states

power: 15mW, 2Hz flashing and steady on mode

Equipped with signal fire stripper

Invisible storage for easy accessZSQ-09

Signal Fire Stripper

Reduce carrying and improve work efficiency

7800mAh lithium battery

Dual charging pathIn full state, 240 cores can be continuously fused and heated

Charging time ≤3.5 hours

The battery can be removed

and charged separately

Cooling rack

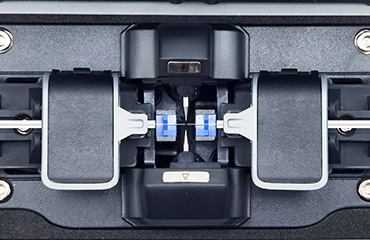

Expandable and closable3 in 1 fiber holder

SM, MM, bare fiber, pigtail, Drop cable , multi fiber cable

EXQUISITE DETAILS

The buttons are clear and beautifulUltra thick protective rubber pad

Thickened buffer structure provides maximum protectionOutdoor splicing fiber

compact and portable

Combination hanging chain

Climbing homework

Basic Parameter

| Fiber alignment | Core/cladding |

|---|---|

| Motor number | 6 motors |

| Splicing time | 6s |

| Heating mode | 15s, can be customized according to the external environment |

| Fiber type | Single-mode fiber (SMF/G.652), BIF/G.657); Suitable for single mode, multi-mode, bare fiber, tail fiber, drop cable, jumper, invisible fiber fusion; |

| The cladding diameter | 80-150μm |

| Splicing loss | 0.02dB(SM)、0.01dB(MM)0.04dB(DS/NZDS) |

| Splicing mode | Automatic focusing core alignment, conventional/high precision welding |

| Splicing way | Automatic, semi-automatic |

| Fiber holder | Three in one fixture, no need to change, suitable for single/multi-mode, multi-core cable/bare fiber, tail fiber, jumper fiber,drop cable |

| Fiber cleaver | Equipped with electric high-precision cleaver |

| VFL | The machine comes with: power: 15mW, 2Hz flashing and steady on mode |

| OPM | Wavelength: 850nm; 1300nm, 1310nm, 1490nm, 1550nm, 1625nm/Measurement range: -50+26dbm Absolute error: <0.3dB (-50dbm ~+3dBm range) |

| Battery capacity | 7800mAh large capacity lithium battery charging time ≤3.5; It can continuously weld and heat about 240 cores |

| Magnification | 320x (X or Y axis single display) 200x (x and Y axis dual display) |

| Fiber diameter | Coating diameter: 80-150μm/Coating diameter: 100-1000μm |

| Cutting length | Coating layer 250μm below: 8-16mm/coating layer 250-1000μm: 16mm |

| Heat shrink tube | 60mm、50mm、40mm、25mm |

| Tensile testing | standard 2N |

| Display | 5 inch TFT color display screen |

| External lighting | USB port can be connected with EXTERNAL LED light, convenient for night construction |

| Charge mobile device | The USB port can charge mobile devices such as mobile phones |

| Boot time | 1s, boot can enter the working mode |

| Data is stored | Unlimited, machine storage 1000 groups, the excess part can be stored in the server, can export data. |

| Wireless communication | Based on bluetooth 4.2 protocol standard, the working band is 2.4GHz, the maximum transmission range is 60m |

| Software upgrade | Mobile phone APP Internet update, enable Bluetooth synchronization upgrade machine software |

| Management function | The equipment owner can be bound as the highest authority, and can remotely view the welding records,welding time, loss, etc. through the mobile phone APP. The number of welding times or working time of the equipment can be set. The manager can effectively manage a single or multiple equipment. |

| Interface | USB2.0 (Type A) can be used to connect external LED lights and charge mobile devices |

| Return loss | Better than 60 db |

| Product protection | Waterproof, dustproof and fall proof |

| Power supply | Input AC100-240V 50/60Hz, output DC13.5V/4.8A, the current power mode can be identified, real-time monitoring of the current battery level |

| The work environment | Temperature: -15 ~ +50℃, humidity: < 95%RH (no condensation), working altitude: 0 ~ 5000m, maximum wind speed: ≤15m/s |

Accessories in the tool box

SERVICE COMMITMENT

Once you buy our Fusion Splicer machine, we offer original packaging new machine, the products meet industry-related quality standards and commitment to enjoy the following services provided by our company:

Five years warranty, but these circumstances are not within the scope of this provision.

A、Except for the cleaver, Miller clamp, stripping pliers, fiber holders and other tools whose life depends on the frequency of use and the use of the environment.

B、Electrodes are consumables, it is in termination after the electrodes splicing 3,000 times.

C、Battery and power adapter warranty for one year, it is in free warranty where it is damaged or can not be charged in one year.

D、Due to natural disasters and other outside force majeure caused by failure or damage.

E、Human factors cause the machine to strong shocks, drops and other factors result in damage.

F、Without our company authorization, unauthorized disassembly, repair situation; at the same time our company reserves the right to further responsibility.

G、The customer bear the out and home shipping cost.