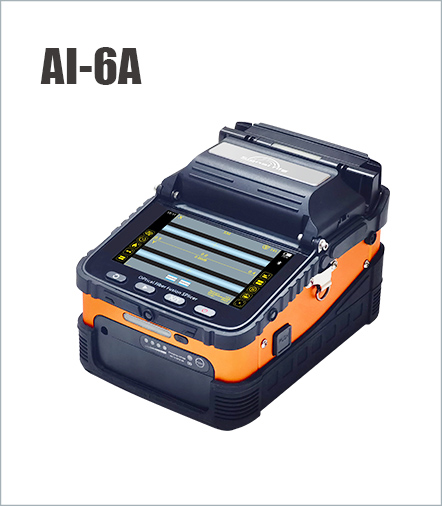

Fusion splicer series model

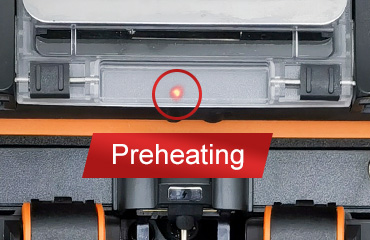

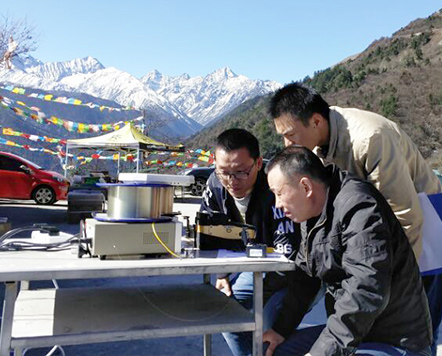

Signal Fire optical fiber fusion splicer AI-6A/6C/7C/8C/9 use the latest core alignment technology with auto focus and six motors, it is a new generation of fiber fusion splicer. It is fully qualified with 100 km trunk construction, FTTH project, security monitoring and other fiber cable splicing projects. The machine uses industrial quad-core CPU, fast response, is currently one of the fastest fiber splicing machine in the market; with 5-inch high-definition color display screen, the operation is simple and intuitively; and up to 300 times focus magnifications, making it is very easy to observe the fiber with naked eyes. 6 seconds speed core alignment splicing, 15 seconds heating, the working efficiency increased by 50% compared to ordinary splicing machines. Large capacity lithium battery, fully charged state can splice & heat 260 fibers, also the splicer machine can charge the phone, to solve your trouble when your phone has no power at outdoor working. Under the conditions of rigorous testing, the performance is still outstanding; toolbox is small, exquisite, durable, and with unique bench design. The design of operating platform reflects the humanistic care; unique lighting design, it is convenient for night construction or repair. Screen brightness is adjustable and it is convenient for outdoor sunshine environment operation. The core parts are using imported brands, aviation metal body material with exquisite details. With the combination of advanced technology and design, the new generation of optical fiber fusion splicer will bring you a reliable and comfortable user experience.